Grip-Clamps® Roller-Cam Clamps™

Aladco® offers repair assessment for the legacy clamp product line. For more information, please contact Aladco® 262-544-5994.

Grip-Clamps®

Product Overview

Aladco® offers a line of pneumatic Grip-Clamps® ideal for automotive, food and other industrial manufacturing requirements. Special heat-treated, alloy steel components offer superior wear and strength. Adjustable cushions provide smooth, long operation. Standard arms allow for a wide range of tooling clearances. We offer toggle lock and power lock clamps allowing greater flexibility to fit all your manufacturing needs.

Toggle vs Power

The toggle clamp is used for added safety and is designed so that the linkage goes over-center and remains in a positive locked position even in the absence of air pressure. The toggle clamp is unlocked only by the cylinder powering the linkage back through the over-center locked position.

The power lock is designed so that the linkage does not go over-center providing for variable clamping thicknesses.

We recommend the use of Aladco® check valves for toggle and power applications to maintain air pressure and clamping force.

Grip-Clamp® Resources:

Grip-Clamp® 2501 – One Arm Toggle Lock Information

Grip-Clamp® 2502 – Two Arm Toggle Lock Information

Grip-Clamp® 2506 – 90° Toggle Lock Information

Grip-Clamp® 2511 – One Arm Power Lock Information

Grip-Clamp® 2512 – Two Arm Power Lock Information

Grip-Clamp® 2516 – 90° Power Lock Information

Features:

- 2500 Grip-Clamp® Family:

- The largest gripper available – 10,900 inch-lbs. clamping force

- Arm torque load capacity of 56,000 in-lbs

- Powered by a 4.0″ bore cylinder

- Grip-Clamp® mechanically toggle locks in the over-center clamped position

- Standard 90-degree arm openings

- Custom arms and special openings available

- Enclosed 1.0″ cylinder rod prevents rod failure

- All heat treated precision ground alloy steel components for reliability

- Grease fittings for re-lubrication

- NFPA mounting to fit a quality cylinder

- Hydraulic cylinder option available

- Patented and Made in Waukesha, Wisconsin USA

Please Note: The 2600 Grip-Clamp® Family is no longer in production. Contact Aladco® for information about a rebuild or repairs.

Roller-Cam Clamps™

Product Overview

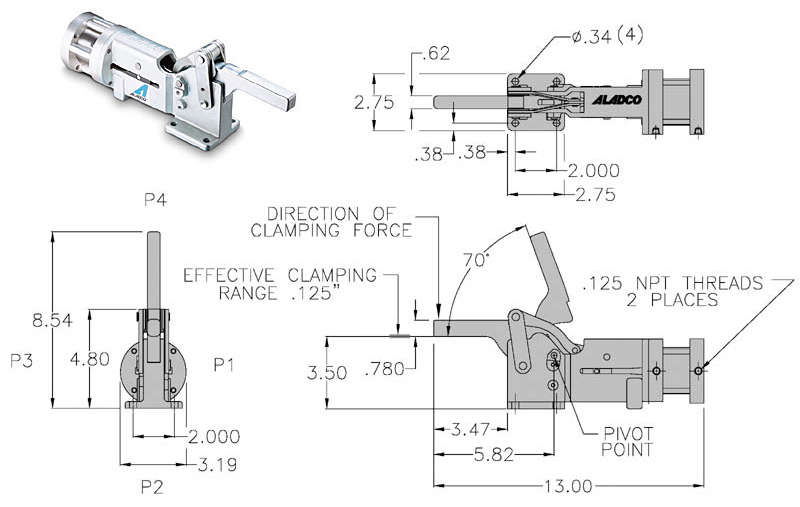

The Roller-Cam Clamp™ has specialized applications and is a patented Aladco® product. The lightweight, compact clamp is ideal for fragile material handling such as glass and plastics. The clamping force is controllable and does not apply a crushing pressure. It has a unique variable clamping range of 0” to 0.12” to accommodate material variations and stacking tolerances.

The clamp’s engineering design and material strength provide a dependable, durable product to fit your clamping needs.

Roller-Cam Clamp™ Resources:

Features:

- Controllable clamping force

- Eliminates crushing pressures

- Accommodates material variations and stacking tolerances

- Variable clamping range is 0 to 0.12″

- Eliminates frequent tooling adjustments

- Standard 70 degree arm opening

- Superior size-to-holding force ratio

- Lightweight and compact in size

- Enclosed 0.75″ cylinder rod prevents rod failure

- Powered by a 2.0″ bore cylinder

- All heat treated, precision ground alloy steel components for reliability

- Patented and Made in Waukesha, Wisconsin USA

Please Note:

- Aladco® Roller-Cam Clamps™ are legacy products. Supplies of new units are limited.

- Repair of Roller-Cam Clamps™ by Aladco® is also available.