Product Overview

Aladco® Clean-Check® valve is a normally closed check valve that can be overridden by air piloting or manually to allow two-way flow. The tightly sealed Clean-Check® valves are used on pneumatic devices to stop air release when the device is stopped, which prevents drifting of the device and any attached load. Clean-Check® valves are unique in that they can be used in environments that need to stay very clean, but they also can tolerate exposure to external dirt and liquids.

The Clean-Check® valve is fully sealed for use in clean/sanitary environments without its function being affected. The valve is able to tolerate: dust, dirt, oil, grease, detergent, cleaning solutions and cutting fluids.

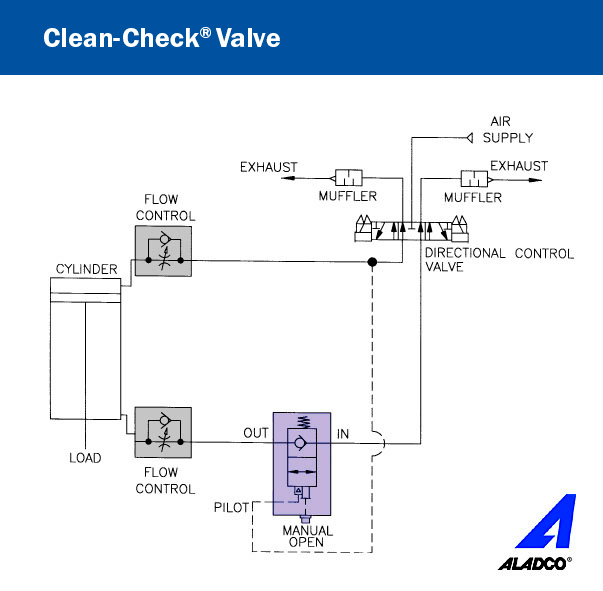

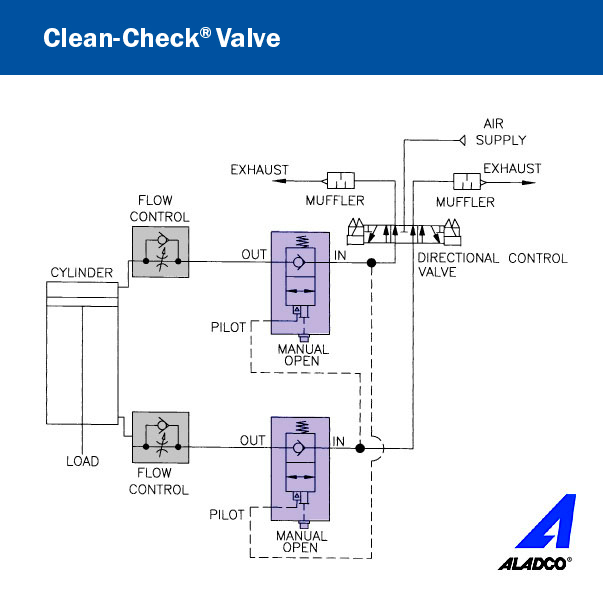

A typical use of a Clean-Check® valve involves combining it with a direction control valve to control air flow from ports of a pneumatic device. With an appropriate combination of direction control valves and other pneumatic components, a cylinder position control system using a Clean-Check® can handle both normal position control and standby or safety stop conditions. An example schematic for a double acting cylinder is shown. A combined valve system can have excellent fail-safe and assured control properties.

Features

- Superior, self-cleaning ball seal provides long product life

- Exceeds ANSI Class VI Leak Standard (bubble tight)

- Body is made of high strength, lightweight, anodized 6061 aluminum alloy (Stainless Steel 303 is optional in some models)

- Variety of porting options

- Designed for use with lubricated or non-lubricated air systems

- Tamper resistant with no required maintenance

- Prevents load drift and provides rapid stopping of load

- Fully sealed for use in clean/sanitary environments

- Patented and Made in Waukesha, Wisconsin USA

- Standard 3-year warranty

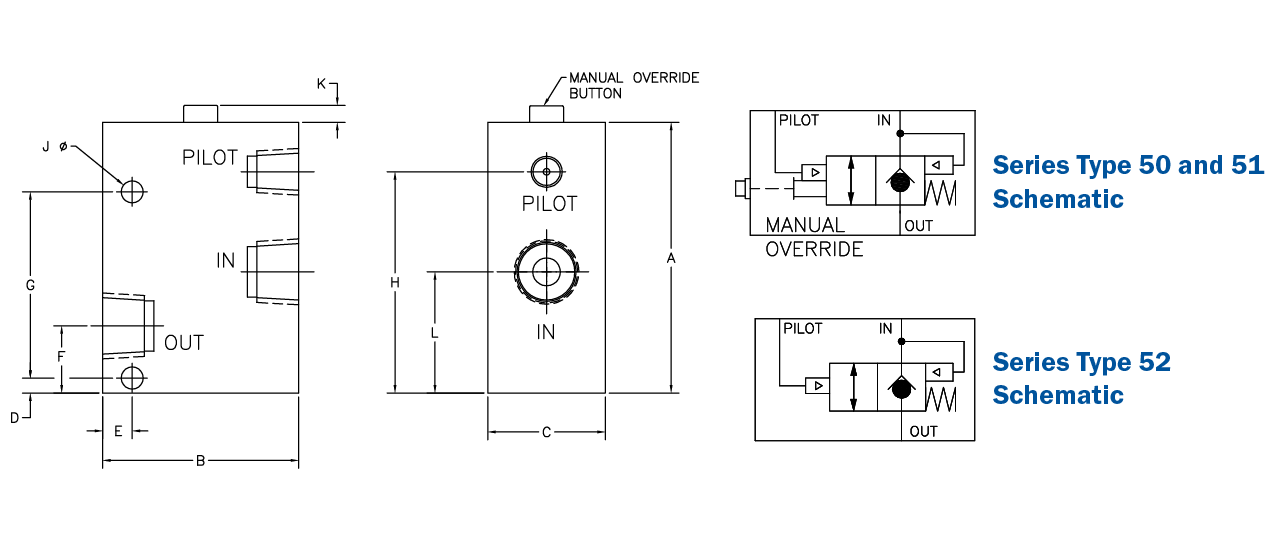

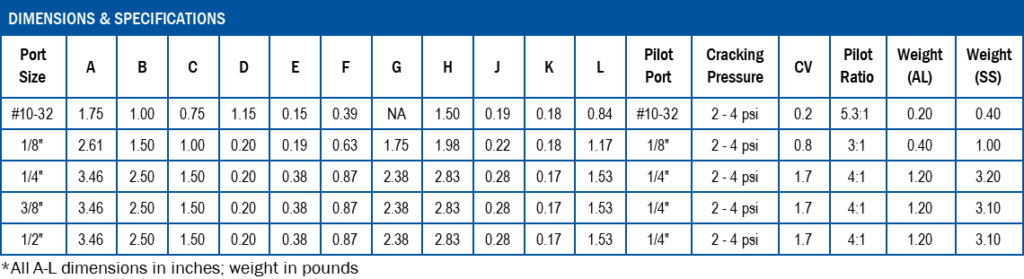

Clean-Check® Pneumatic Check Valve Dimensions

Additional Notes:

- Standard seal is Buna-N (30° to 250°F temperature range); Viton® (-15° to 400°F temperature range) is also an available option

- MTTF is over 100 million cycles for Buna-N seals and over 40 million cycles for Viton® seals

- NPTF Ports conform to ASME B1.20.1-2013 Pipe Threads, General Purpose (Inch)

- BSPP (G) and M5 Ports conform to ISO 16030:2003: Pneumatic fluid power – Connections – Ports and stud ends

- Operating pressure is 15 to 120 psi

- Operating temperature 30° to 150°F

- 10-32 UNF models have only one mounting hole

Disclaimer:

- This valve has not been designed for use on vacuum, air over oil or high pressure applications

- Technical details subject to change without notice

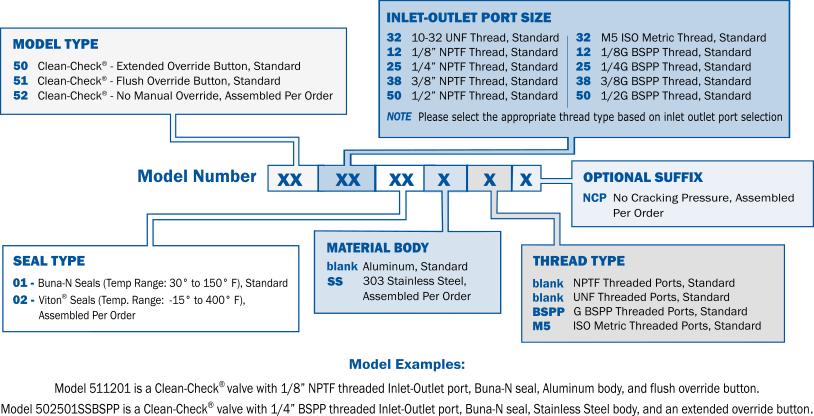

Model Ordering Information

Product Configurator

The U.S. list price displayed is for individual quantities of 1-24. Contact your Aladco® Distributor or Aladco® for volume pricing of 25 or more valves.

Additional information

| Model Type | 50 : Clean-Check Valve – Extended Manual Override, 51 : Clean-Check Valve – Flush Manual Override, 52 : Clean-Check Valve – No Manual Override |

|---|---|

| Inlet-Outlet Port Size | 32 : 10-32 UNF Port, 32 : M5 ISO Metric Port, 12 : 1/8 Port, 25 : 1/4 Port, 38 : 3/8 Port, 50 : 1/2 Port |

| Seal Type | 01 : Buna-N Seals, 02 : Viton Seals |

| Material Body | [blank] : Aluminum, SS : 303 Stainless Steel |

| Thread Class | [blank] : NPTF Thread Class, [blank] : UNF Thread Class, BSPP : G BSPP Thread Class, M5 : ISO Metric Thread Class |

| Optional Suffix | [blank] : No Optional Features, NCP : No Cracking Pressure |

Technical & Application Files

Clean-Check® Information • 1/8″ Clean-Check®/Nu-Check® Comparison • 10-32 Clean-Check®/Nu-Check® Comparison •

Clean-Check® Full Circuit Diagram • Clean-Check® CAD Files