Product Overview

The Aladco® Nu-Check® valve is a normally closed check valve that can be either overridden manually or by air piloting to allow two-way flow. The tightly sealed Nu-Check® valves are used on pneumatic devices to prevent air from flowing towards the ball check upon loss of pilot pressure which will prevent the device from drifting.

The Nu-Check® valve, designed specifically for pneumatics, is a patented Aladco® product. It was the first check on the market with both manual and pilot release capabilities. The unique bubble-tight seal keeps devices from drifting towards the “checked” position in the event of pressure loss or fluctuation. To release the seal, press the manual override button or operate the pilot.

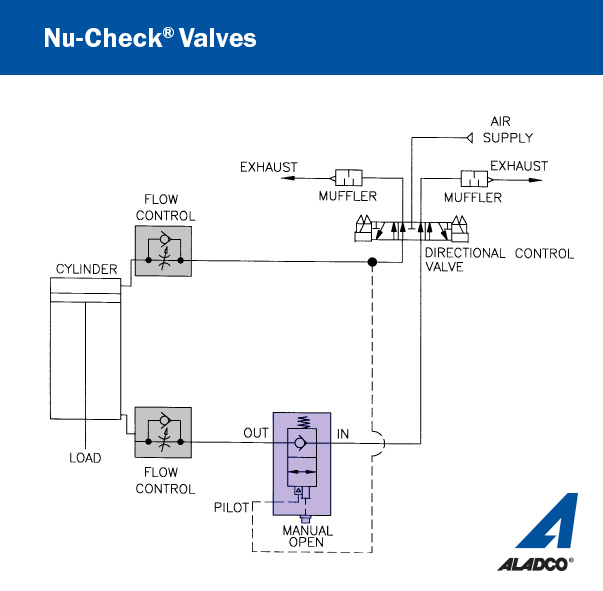

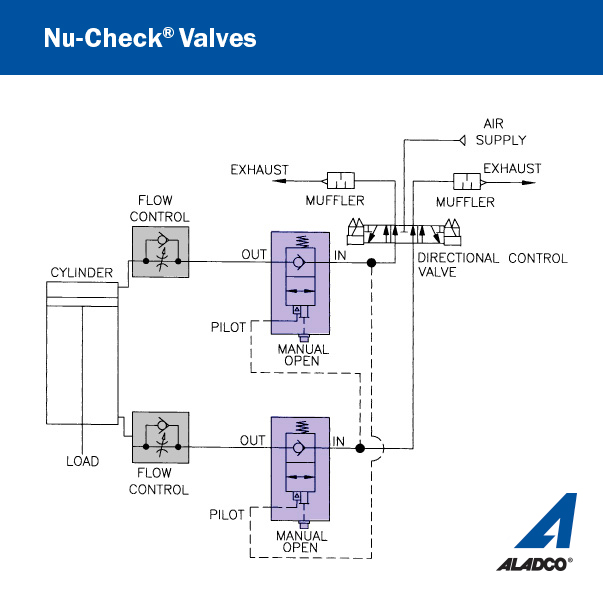

A typical use of a Nu-check® valve involves combining it with a directional control valve to restrict when air is allowed to flow from ports of a pneumatic device. With an appropriate combination of directional control valves and other pneumatic components, a cylinder position control system using Nu-Check® valves can accommodate for both normal position control as well as rapid motion stoppage and position holding. Two example schematics are shown to illustrate potential uses of the Nu-Check® valve. Figure 1 shows an example of a system using a single Nu-Check® valve that will prevent the cylinder or load from falling upon pressure loss or upon loss of power to directional control valve. Figure 2 shows an example of a system using two Nu-Check® valves that will stop the cylinder in from moving in either direction upon pressure loss or upon loss of power to directional control valve.

Aladco® highly recommends the use of spring centered 3 position 5 way centered vented valves for directional control with the use of Nu-Check® valves.

Features

- Superior, self-cleaning ball seal provides long product life

- Exceeds ANSI Class VI Leak Standard (bubble tight)

- Body is made of high strength, lightweight, anodized 6061 aluminum alloy

- Variety of porting options

- Designed for use with lubricated or non-lubricated air systems

- Tamper resistant with no required maintenance

- Prevents load drift and provides rapid stopping of load

- Patented and Made in Waukesha, Wisconsin USA

- Standard 3-year warranty

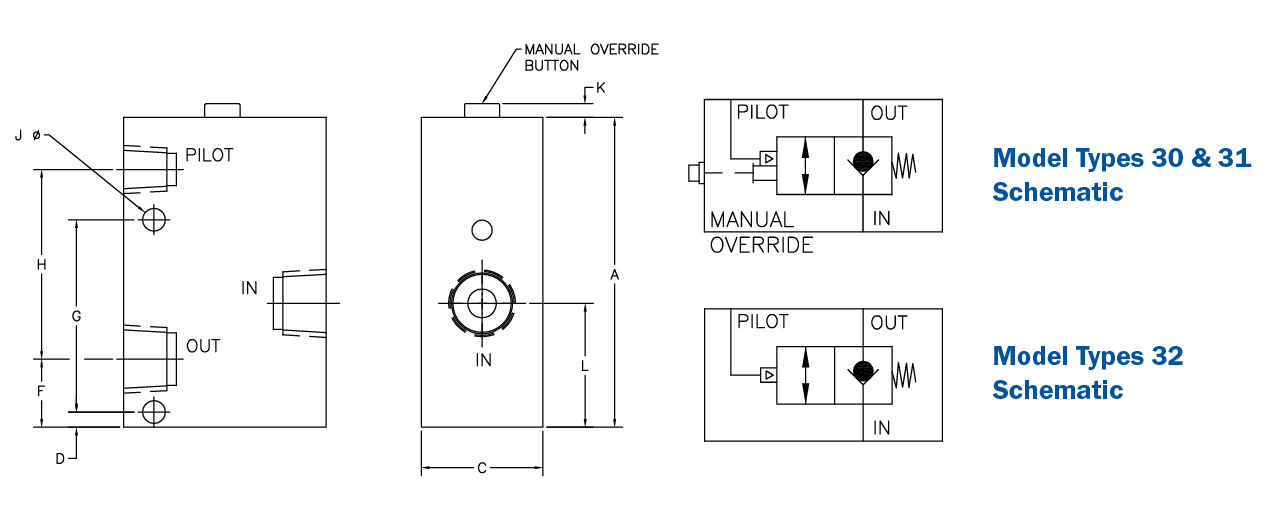

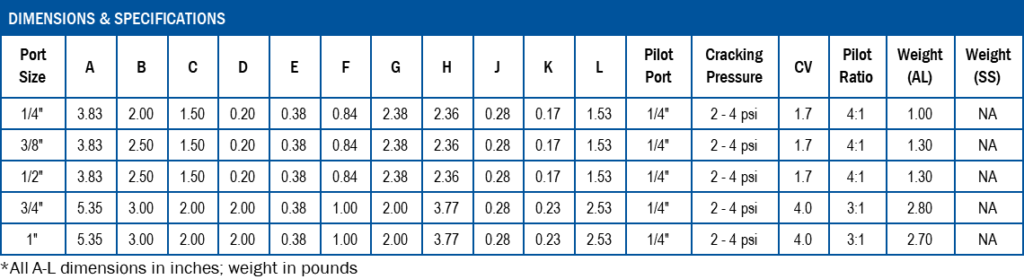

Nu-Check® Pneumatic Check Valve Dimensions

Disclaimer:

- Technical details subject to change without notice

Additional Notes:

- Standard seal is Buna-N (30° to 250°F temperature range); Viton® (-15° to 400°F temperature range) is also an available option

- MTTF is over 100 million cycles for Buna-N seals and over 40 million cycles for Viton® seals

- NPTF Ports conform to ASME B1.20.1-2013 Pipe Threads, General Purpose (Inch)

- BSPP (G) and M5 Ports conform to ISO 16030:2003: Pneumatic fluid power – Connections – Ports and stud ends

- Operating pressure is 15 to 150 psi

- Operating temperature 30° to 150°F

- 10-32 and 1/8″ port sizes are no longer available as Nu-Check® options – please see our line of Clean-Check® pneumatic valves for compatible configurations

- Stainless steel 303 is no longer an available option for Nu-Check® configurations – please see our line of Clean-Check® pneumatic valves for stainless steel valve options

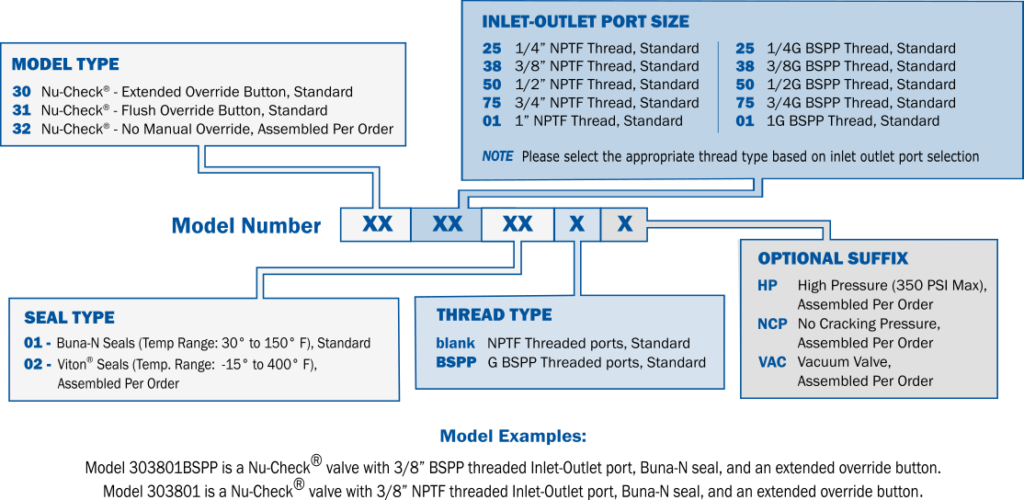

Model Ordering Information

Product Configurator

The U.S. list price displayed is for individual quantities of 1-24. Contact your Aladco® Distributor or Aladco® for volume pricing of 25 or more valves.

Additional information

| Model Type | 30 : Nu-Check Valve – Extended Manual Override, 31 : Nu-Check Valve – Flush Manual Override, 32 : Nu-Check Valve – No Manual Override |

|---|---|

| Inlet-Outlet Port Size | 25 : 1/4 Port, 38 : 3/8 Port, 50 : 1/2 Port, 75 : 3/4 Port, 01 : 1.0 Port |

| Seal Type | 01 : Buna-N Seals, 02 : Viton Seals |

| Thread Class | [blank] : NPTF Thread Class, BSPP : G BSPP Thread Class |

| Optional Suffix | [blank] : No Optional Features, HP : High Pressure (350 psi maximum), NCP : No Cracking Pressure, VAC : Vacuum |